Detailed Product introduction of Fuel Tanker Trailer-ZW Vehicle

Details Product Introduction of 3 Axle 45000L Fuel Tank Semi Trailer---ZW Group

ZW Group 3 Axle 45000L Fuel Tank Semi Trailer is a high-performance liquid transportation solution designed for the safe, efficient, and cost-effective delivery of petroleum products, diesel, gasoline, and other liquid fuels.

Built with precision engineering and robust materials, this tri-axle fuel tanker is optimized for both domestic distribution and long-distance cross-border fuel transport.

Its 45,000-liter loading capacity, combined with a heavy-duty chassis and premium axle system, ensures excellent stability, durability, and payload efficiency.

Whether you operate in Africa, Southeast Asia, the Middle East, or South America, the ZW Group fuel tanker semi trailer is built to meet international transport standards and adapt to diverse road conditions.

Key Specifications

Total Capacity: 45,000 liters (45 cubic meters)

Compartments: Customizable from 1 to 7 compartments for multi-fuel transport

Axles: 3 heavy-duty axles (13T/16T capacity per axle, FUWA/BPW optional)

Suspension: Mechanical or air suspension (optional for different terrains)

Tires: 12R22.5 or 315/80R22.5 premium tires (Triangle, Linglong, or Michelin)

Brake System: WABCO air brake system with emergency relay valve

Material: High-strength carbon steel or aluminum alloy

Discharge System: Bottom or side discharge with API valves and emergency shut-off

Manhole Covers: 500mm diameter with pressure relief & anti-overflow protection

Painting: High-quality anti-corrosion paint with customized colors & branding

Landing Gear: JOST 28T heavy-duty landing legs

King Pin: 2” or 3.5” JOST standard

Product Features

1 Universal Advantages

Premium Painting Technology

ZW Group applies automatic shot blasting, anti-rust primer, and polyurethane finish coating to ensure 10+ years corrosion resistance.

Multiple color options & customized company logo branding available for fleet identity.

Axle System

Equipped with FUWA/BPW/ZW -certified 13–16T axles, ensuring long lifespan, low maintenance, and excellent load capacity. Axles undergo high-precision alignment to reduce tire wear.

High-Quality Tires

Our trailers use international-standard tubeless radial tires with anti-skid tread pattern for stability in wet or off-road conditions. Each set is tested for uniformity and balance.

Suspension System

Choose between mechanical leaf spring suspension (ideal for rough roads) or air suspension (for smoother ride & cargo protection). Both designed for heavy-load stability.

2 Detail Advantages

Seamless Welding Technology – Automated submerged arc welding for leak-proof tank seams.

Reinforced Chassis – High-tensile steel, double main beams for maximum strength.

Safety Valves & API Fittings – International standard fuel discharge fittings for quick loading/unloading.

Anti-wave Baffles – Internal anti-surge plates reduce liquid movement for safe handling.

Pressure & Vacuum Protection – Prevents tank deformation during loading/unloading.

LED Lighting System – Energy-efficient, weatherproof lights for night operation.

Manufacturing Process

Raw Material Selection – Only high-strength carbon steel or aluminum alloy plates are sourced from certified suppliers.

CNC Cutting & Shaping – Advanced plasma cutting ensures precise tank dimensions.

Automatic Welding – Submerged arc welding produces uniform seams, minimizing leaks.

Internal Cleaning & Polishing – Tank interior is sandblasted and cleaned for fuel purity.

Painting & Coating – Multi-layer coating process for long-lasting corrosion resistance.

Assembly – Axles, suspension, braking system, and accessories are installed by skilled technicians.

Quality Inspection – Each unit undergoes X-ray weld inspection and dimensional accuracy tests.

Load Testing & Quality Assurance

Every 3 axle 45000L fuel tank semi trailer passes strict load testing before delivery:

Hydrostatic Pressure Test – Tank is filled with water to check for leaks.

Air Tightness Test – Detects any microscopic leaks in weld seams.

Brake & Suspension Test – Ensures stable performance under full load.

Road Simulation Test – Replicates different terrains to verify durability.

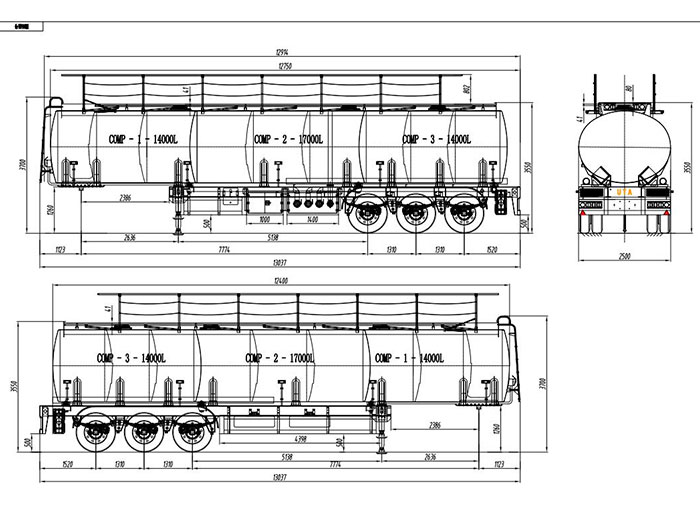

Technical Drawings

ZW Group provides detailed CAD drawings for each trailer order, including:

Tank dimensions & compartment layout

Chassis structure & axle placement

Valve and manhole positioning

Custom branding placements

Advantages of ZW Group 3 Axle 45000L Fuel Tank Semi Trailer

Large 45,000 Liter Capacity for Efficient Fuel Transport

Maximizes each trip’s payload, reducing fuel delivery costs and increasing operational efficiency for diesel tanker semi trailer and petroleum transport trailer fleets.

High-Strength Carbon Steel or Aluminum Alloy Tank Body

Built with durable, corrosion-resistant materials to extend service life of the oil tanker semi trailer even in harsh climates.Premium FUWA/BPW Axles with High Load Capacity

Ensures stable performance for heavy loads, making this tri-axle fuel tanker trailer ideal for long-distance fuel transport.Advanced Multi-Layer Anti-Corrosion Painting System

Enhances resistance to rust and weather damage, keeping the fuel tank truck trailer looking new for years.Customizable Compartment Design

Multiple compartments allow transport of different fuel types in one trip, improving the multi-fuel tanker trailer versatility.International Standard API Valves & Manhole Covers

Improves safety and speed during loading and unloading, meeting fuel tanker trailer global certification requirements.Heavy-Duty Suspension System

Optional mechanical or air suspension adapts to regional road conditions, ensuring diesel fuel tanker semi trailer stability.Internal Anti-Wave Baffles

Reduces liquid surge during braking or turning, improving safety for the petrol tanker semi trailer.Complete Safety System

Includes emergency shut-off valves, pressure relief devices, and LED lighting for safe night operations with the 45000 liter oil tanker trailer.Global Export Experience & After-Sales Support

Proven track record in exporting fuel tanker semi trailers to Africa, Southeast Asia, and the Middle East with full spare parts supply.

Frequently Asked Questions (FAQ)

Q1: What fuel types can this tanker carry?

A: Diesel, petrol, kerosene, ethanol, and other light oil derivatives.

Q2: Can the tanker be made from aluminum?

A: Yes, aluminum tankers are available for weight reduction and better fuel economy.

Q3: How long is the delivery time?

A: Standard models: 20–25 working days; Custom designs: 30–35 days.

Q4: What’s the lifespan of the trailer?

A: With proper maintenance, 10–15 years.

Q5: Can you provide OEM/ODM service?

A: Yes, we can customize design, color, branding, and accessories.

Q6: Do you offer spare parts?

A: Yes, we supply spare axles, tires, valves, and repair kits worldwide.