Responding to Logistics Upgrade: Why Burkina Faso Urgently Needs Fence Semi‐Trailers

Responding to Logistics Upgrade:

Why Burkina Faso Urgently Needs Fence Semi‐Trailer

Introduction

Burkina Faso’s geography as a landlocked West African nation positions it as a critical inland transit hub. However, its underdeveloped road and rail infrastructure creates bottlenecks for the flow of agricultural, industrial, and consumer goods.

As the government accelerates road and rail upgrades, the demand for robust cargo vehicles—especially fence and box semi-trailers—has become pressing.

This article explores infrastructure trends, presents a real-world customer case, and showcases the ZW Group Fence semi-trailer advantages for the Burkinabe market.

I. Infrastructure Revolution in Motion

1. Road Upgrades Across Key Corridors

The Bobo-Dioulasso–Banfora–Côte d’Ivoire border corridor and the Banfora–Orodara route (197 km total) are undergoing major rehabilitation with a US $267 million budget, financed by AfDB, IsDB, EU, and national government, enhancing trade with Côte d’Ivoire and Mali.

Additionally, Burkina Faso plans an investment of ~$383 million to upgrade five primary roads, including a 200 km motorway toward the Ivorian border, significantly reducing transport times and costs.

A flagship initiative under the World Bank—a US $216 million “SKBo Basin of Integration” project—is improving climate-resilient road and rail connectivity between Sikasso (Mali), Korhogo (Ivory Coast), and Bobo-Dioulasso (Burkina Faso), aiming to benefit nearly 3.9 million people.

2. Railway Expansion and Modernization

A $53.1 million investment, part of a broader plan triggering a 1.4 billion USD investment in the Abidjan–Kaya rail axis, will begin in 2026, targeting modern rail infrastructure and local industrial capacity in rail asset manufacturing

Burkina Faso is also advancing the standard-gauge Sahel Railway, connecting Ouagadougou to emerging networks in Mali, Niger, Benin, and Ghana, enhancing multimodal logistics

3. Challenging Legacy Conditions

Despite progress, only ~2,000 km of the roughly 12,500 km national road network is paved; many roads lack proper signage, markings, or guardrails. Firms cite road conditions as their biggest logistical constraint

Continued rural road projects like deploying 1,000 km of rural roads are underway, aiming to connect remote agricultural areas to main corridors

II. The Supply Chain Need: Fence vs. Box Semi-Trailers

1. Why Burkina Faso Needs Them Now

As road quality improves and trade corridors become more reliable, transportation capacity must increase—particularly for both versatile open cargo (fence trailers) and secure enclosed freight (box trailers).

Rural road expansion means trailers must be durable and able to handle mixed terrain conditions.

Increased exports of agricultural and mining products demand both high payload capacity and cargo protection.

2. Customer Benefit Snapshot: ZW Group Fence Semi-Trailer

Case Illustration: A grain cooperative in Bobo-Dioulasso partnered with a ZW Group dealer to supply a 3-axle, 60-ton fence semi-trailer to transport millet and maize to Abidjan.

Operational Gains: The cooperative increased its cargo volume per trip by 35% and cut turnaround time by 25%, thanks to the trailer’s heavy-duty steel construction and advanced suspension.

Cost Efficiency: Over the first six months, transport cost per ton dropped by 18% due to fewer trips and lower maintenance needs.

Safety and Reliability: Reinforced fencing and robust frame minimized spillage and damage on rough rural roads.

Local Support and Parts: ZW emerging spare parts network in Ouagadougou allowed for 50% faster maintenance cycles.

III. ZW Group Advantages & Key Selling Points

Heavy-Duty Build for West African Conditions

ZW Group fence semi-trailers are tailored for the rigors of West Africa—featuring high-strength steel, corrosion-resistant coatings, and reinforced axles. Range includes 2 axle-6 axle ,40ton-100ton models.

Scalable Options

For versatile loading needs, ZW offers both fence and box semi-trailers, allowing clients to choose based on cargo type, security requirements, and payload.

After-Sales Support

ZW provides design customization, spare parts, and maintenance training—especially valuable in regions where poor road conditions accelerate vehicle wear.

Payload Optimization

High payload capacities translate directly into lower cost per ton and fewer trips along key corridors like the Trans-Sahelian Highway and SKBo routes

IV. Why ZW Group Fence Semi Trailer is the Preferred Choice

1. Engineering Excellence

High‑Strength Q345B Steel: Provides superior durability and resistance to bending under heavy loads.

Advanced Welding Technology: Robotic welding ensures uniform seams, extending service life.

Optimized Suspension: Air and mechanical suspension options reduce road impact and improve ride stability.

2. Customization Options

ZW Group offers multiple sidewall heights, axle configurations (2‑ to 4‑axle), and brake systems to match diverse cargo needs.

3. Operational Benefits

Increased Payload Capacity: Up to 80 tons gross capacity reduces total trips.

Fuel Efficiency: Aerodynamic design lowers fuel consumption by 5–8%.

Safety Features: Anti‑lock braking systems (ABS) and reinforced side rails improve road safety.

4. After‑Sales and Training

ZW provides on‑site driver training, maintenance manuals in French and English, and a dedicated service hotline for West African customers.

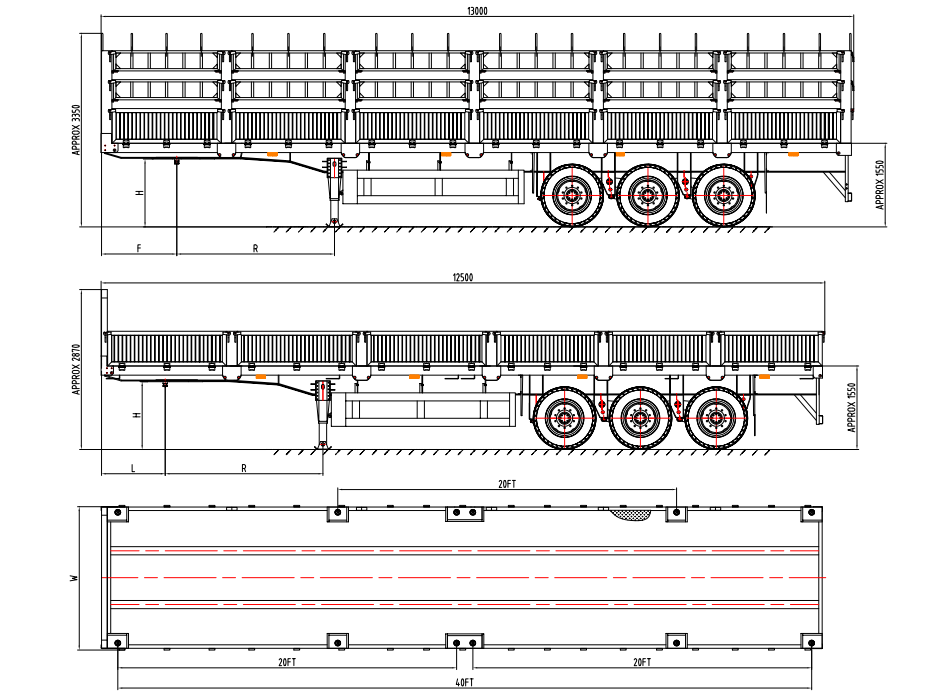

Technical Specifications & Configurations

| Model Variant | Dimensions (mm) | Payload | Axles | Frame Details |

|---|---|---|---|---|

| 2-Axle | 9500–13000 × 2500 × 2800–3800 | 30–60 t | 2×13–16 t (FUWA/BPW) | 500 mm Q345B beam; 12–14 mm plates |

| 3-Axle (12.5–13 m) | 12500–13000 × 2500 × 2800–3800 | 30–80 t | 3×13–16 t | 16 mm upper, 10 mm middle, 18 mm bottom plate Q345B |

| 4-Axle | Same as above | 40–100 t | 4×13–16 t | Q345B frame with 20 mm bottom plate |

Local Industry Insight & Data

According to the Burkina Faso Transport Association (2025):

Average payload per trailer: 40–50 t due to local road limitations.

Trailer maintenance costs: ~18% of operating expenditure annually.

Downtime: 15–20 days/year due to breakdowns.

Projected Impact with ZW Group 3-Axle 60 t Trailer:

Maintenance saving: ~40% reduction (to ~10%).

Downtime decrease: From 18 to ~8 days/year.

Return on Investment: Within 2 years via increased uptime and cost savings.

Conclusion

Burkina Faso is entering a critical phase of logistics modernization. The expansion of climate‑resilient road networks and multimodal corridors will unlock significant economic potential, but only if transport capacity keeps pace.

ZW Group Fence Semi Trailer delivers the heavy‑duty performance, customization, and local support required to meet this demand.

For logistics operators looking to reduce costs, boost efficiency, and prepare for the next decade of growth, ZW Group stands as the trusted partner for Burkina Faso’s evolving freight landscape.