How ZW Group Fuel Tanker Semi Trailer Helped a Tanzanian Fleet Cut Fuel Theft by 15%

How ZW Group Fuel Tanker Semi Trailers Helped a Tanzanian Fleet Cut Fuel Theft by 15%

Discover how a leading Morogoro logistics fleet reduced fuel theft by 15% and eliminated rollover risks using ZW Group’s specialized Anti-Theft Fuel Tanker Trailers. A deep dive into petrol transport safety in Tanzania.

Executive Summary: The State of Fuel Logistics in East Africa

Fuel transport is the pulsating lifeblood of the Tanzanian economy. From the bustling industrial hubs of Dar es Salaam to the remote gold mines in Geita and the agricultural heartlands of the Southern Highlands, diesel and petrol keep the nation moving. However, for logistics companies and fleet owners operating across the East African Community (EAC), the road is fraught with challenges.

High operational costs, rugged terrain, and—most critically—rampant fuel theft (siphoning) threaten the viability of transport businesses. This article details a comprehensive case study of how a major logistics provider in Morogoro transformed their profitability by partnering with ZW Group. By deploying our specialized Anti-Theft Fuel Tanker Trailers, they achieved a massive 15% reduction in fuel loss and significantly improved road safety.

Part 1: The Challenge – The "Black Hole" of Fuel Transit

A leading logistics company based in Morogoro, operating a fleet of 40 heavy-duty trucks, approached ZW Group with a critical operational crisis. Their fleet was tasked with the long-haul transport of diesel from the port of Dar es Salaam to distribution centers in Mbeya and neighboring landlocked countries like Zambia and Malawi.

The Problem: Siphoning and Safety

Despite investing heavily in GPS tracking technology and fuel monitoring software, the client was bleeding revenue.

Sophisticated Theft: Thieves, often working in collusion with drivers or roadside syndicates, had developed methods to bypass standard padlocks and drain fuel without triggering electronic alarms.

The "Blind Spot": Standard tankers offered little physical resistance to tamper attempts during overnight stops.

Road Instability: The route to Mbeya involves winding ascents and varying road qualities. The client had experienced two rollover incidents in the previous year using standard tankers with high centers of gravity, resulting in total cargo loss and environmental fines.

The client needed more than just a trailer; they needed a fortress on wheels.

Part 2: The ZW Group Solution – Engineering Security

ZW Group did not offer a generic, off-the-shelf product. We analyzed the specific modus operandi of Tanzanian fuel thieves and the topography of the Tan-Zam Highway to engineer a customized 45,000 Liter Anti-Theft Fuel Tanker Semi Trailer.

Our solution focused on three pillars: Impenetrable Security, Structural Stability, and Durability.

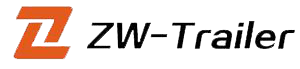

1. The "Safe-Box" Valve Protection System

The most vulnerable point of any fuel tanker is the discharge valve. Standard tankers use exposed valves or simple plastic boxes.

The Innovation: ZW Group installed a reinforced, fully enclosed High-Strength Steel "Safe-Box."

The Mechanism: This box covers the discharge valves entirely. It features a hidden, internal locking mechanism that is inaccessible to bolt cutters or crowbars.

The Impact: Unauthorized access is physically impossible without heavy industrial tools, which are too noisy and slow for roadside theft.

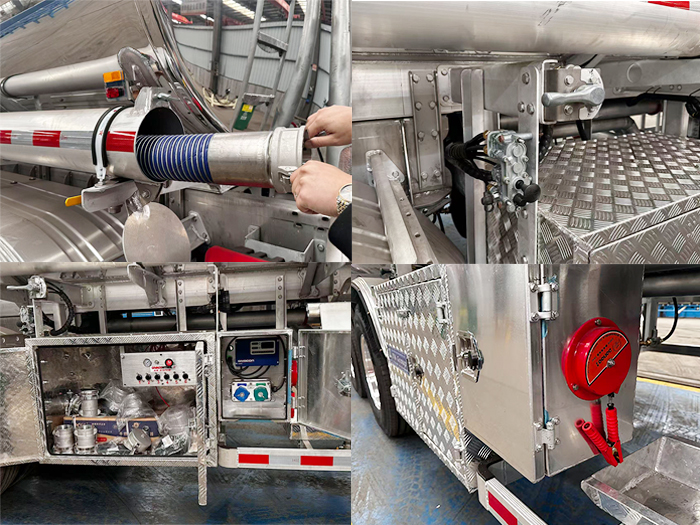

2. Explosion-Proof Anti-Theft Manhole Covers

Thieves often bypass bottom valves by siphoning directly from the top.

The Innovation: We utilized European-standard explosion-proof manhole covers.

The Mechanism: These covers require specialized tooling to open. They are integrated with a built-in breathing valve that balances internal pressure but seals tight against siphoning hoses.

Safety Bonus: In the event of a rollover, these covers are designed to seal automatically, preventing leakage and potential explosions.

3. Low Center of Gravity Design (The Stability Factor)

To address the rollover risk on the winding roads of the Southern Highlands:

The Innovation: We redesigned the tank body shape and chassis integration.

The Mechanism: By employing a "Gooseneck" structure and optimizing the tank's oval curvature, we lowered the tanker's center of gravity by 150mm compared to standard market models.

The Impact: Enhanced stability during cornering and braking, significantly reducing the risk of accidents.

Part 3: The Results – Data-Driven Success

After six months of rigorous operation on the Dar es Salaam – Mbeya corridor, the client reported the following data:

| Metric | Before ZW Group Tanker | With ZW Group Anti-Theft Tanker | Improvement |

| Average Fuel Loss per Trip | 3.5% (Unaccounted) | < 0.2% (Evaporation only) | 94% Reduction in Loss |

| Rollover Incidents | 2 per year | 0 in 6 months | 100% Safety Record |

| Driver Accountability | Low | High | Improved |

| Total Operational Savings | - | $12,000+ per month (Fleetwide) | High ROI |

Client Testimonial: "We used to assume fuel loss was just the 'cost of doing business' in Tanzania. ZW Group proved us wrong. The Safe-Box system has completely stopped roadside siphoning. We are now upgrading our entire fleet." — Fleet Manager, Morogoro

Part 4: Technical Deep Dive – Why ZW Group Tankers Dominate the Tanzanian Market

For fleet owners considering an upgrade, understanding the technical specifications is vital. Here is why ZW Group trailers withstand the harsh African road conditions better than competitors.

Material Science: Carbon Steel vs. Aluminum Alloy

We offer both options, but for this case study, we utilized High-Tensile Q235 Carbon Steel.

Why Steel? While aluminum is lighter, High-Tensile Steel offers superior resistance to the fatigue caused by potholes and "washboard" road surfaces common in remote Tanzania.

Tank Thickness: We use a 6mm thick tank body and 6mm dished ends, ensuring the tank can withstand high pressure and impact.

The Chassis and Suspension: Built for Rough Roads

A tank is only as good as the chassis carrying it.

Main Beams: Made from Q345B high-strength steel, automatically submerged arc welded. This ensures the chassis does not crack under heavy loads (up to 40-50 tons).

Suspension: We utilize heavy-duty mechanical suspension with reinforced leaf springs (10 layers x 13mm).

This is specifically calibrated for East African road conditions, absorbing shocks that would otherwise damage the tank body.

Axles: We partner with top-tier brands like BPW and FUWA (13 ton / 16 ton options). These axles are renowned for their longevity and ease of maintenance in local Tanzanian workshops.

Advanced Welding and Painting

Corrosion is a major enemy in humid coastal areas like Dar es Salaam.

Welding: Our tanks undergo a longitudinal automatic welding process. We perform X-Ray detection on every weld seam to ensure zero defects or leaks.

Painting: The trailers undergo sandblasting to remove rust, followed by an anti-corrosive primer and two coats of Polyurethane paint. This protects the investment from salt air and road grit for years.

Part 5: The Economics of Anti-Theft Technology

Many fleet owners hesitate at the initial cost of premium trailers. However, as our Morogoro client discovered, the Total Cost of Ownership (TCO) is lower with ZW Group.

The "Hidden Cost" of Cheap Trailers

Buying a generic trailer might save $2,000 upfront. However:

Fuel Theft: Losing just 50 liters per trip adds up. At current diesel prices, that is thousands of dollars lost annually per truck.

Repairs: Weak chassis frames crack within 2 years on bad roads, requiring expensive welding repairs and downtime.

Resale Value: Premium tankers hold their value. A rusted, leaking tanker is scrap metal.

Expert Tip: In a market where transport margins are tight, investing in security is investing in pure profit. The payback period for the "Anti-Theft" upgrade is typically less than 3 months based on fuel savings alone.

Part 6: Safety and Compliance in Tanzania

ZW Group ensures all our Fuel Tanker Trailers meet and exceed the regulations set by the Tanzania Bureau of Standards (TBS) and SUMATRA.

Braking Systems: We install the WABCO Emergency Valve and dual-line braking systems. This reduces braking distance and prevents "jack-knifing" during emergency stops.

Compartmentalization: Our tankers can be divided into multiple compartments (e.g., 2, 3, or 4 sections). This allows you to transport diesel and petrol simultaneously, or distribute weight more evenly to prevent liquid surge (sloshing) which destabilizes the truck.

Electrical: 24V electrical systems with LED lights, ensuring visibility during night transit on unlit highways.

Part 7: Frequently Asked Questions (FAQ) for Tanzanian Buyers

Q: Can ZW Group deliver directly to Dar es Salaam?A: Yes. We handle shipping directly to the Port of Dar es Salaam. We can also assist with the documentation required for clearing.

Q: What capacities are available?A: We customize to your needs. Popular sizes in Tanzania include 35,000 Liters, 40,000 Liters, 45,000 Liters, and 50,000 Liters.

Q: Do you provide spare parts?A: Absolutely. We supply a "wear and tear" kit with every trailer, including brake shoes, lights, and valves. We also have a supply chain network to ensure you can get parts quickly in East Africa.

Q: Can this trailer carry other liquids?A: While designed for Petrol/Diesel, we can modify the internal lining to transport crude oil, palm oil, or even water, depending on your contract needs.

Ready to optimize your fleet?

Contact ZW Group today for a customized quote and shipping details to Tanzania.

[View Our Range of Anti-Theft Fuel Tankers] | [Request a Quote via WhatsApp] | [Acquire Technical Specs PDF]